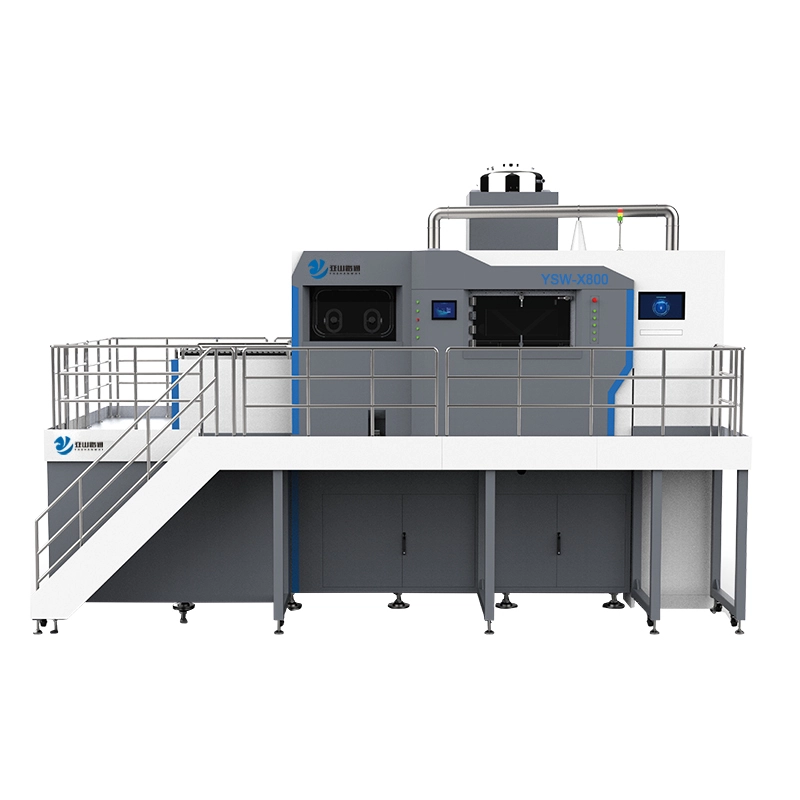

YSW-X800H

The X800H SLM 3D Printer is a cutting-edge solution for high-performance metal additive manufacturing, offering an ideal balance of precision, speed, and versatility. Designed for industries that require complex geometries and high-quality production, the X800H accommodates a wide variety of metal alloys, including superalloys, titanium, stainless steel, and more.

With an expansive build envelope and advanced laser technology, the X800H is capable of producing intricate, high-resolution parts with consistent results. Its high-speed scanning system and customizable powder recoater ensure optimal surface finishes, while the multi-laser setup boosts build rates, significantly reducing production time.

Whether used for rapid prototyping or end-use components, the X800H delivers unmatched reliability and efficiency, making it the perfect choice for sectors like aerospace, automotive, medical devices, and beyond. The X800H redefines what’s possible in metal 3D printing, providing manufacturers with the tools to meet the demands of tomorrow’s most advanced applications.

YSW-X800H+

Ideal for aerospace, medical, automotive and energy sectors, it offers:

-

Scalable productivity with configurable laser options

-

Broad material compatibility

-

Consistent, high-resolution results

-

Reliable 24/7 operation

Transform your production with industrial-grade metal AM technology.

Technical Parameters

| Build Envelope: | 800mm×800mm×1660mm Incl. 80mm Substrate |

| Variable Layer Thickness: | 20~100μm |

| Laser Power: | IPG 500W×6; 500W×8; 500W×10 1000W×6; 1000W×8; 1000W×10 |

| Scanner: | Scanlab High-speed Scanner |

| Field Lens: | Sill f-θ Lens |

| Recoater: | Variable Speed Powder Recoater |

| Build Rate: | ≥150cm³/h Hexa Laser; ≥200cm³/h Octa Laser; ≥250cm³/h Ten Laser |

| Power Dissipation: | ≤45kW |

| Available Material: | Superalloy, Aluminium Alloy, Titanium Alloy, Stainless Steel, Die Steel, copper Alloy, Magnesium Alloy, Cobalt Chromium Alloy, Permalloy, Invar Alloy, Etc |

| Application |

|

Industrial-Grade Metal 3D Printing System

Unlock next-generation manufacturing capabilities with our advanced metal 3D printing platform. Designed for demanding industrial applications, this system combines cutting-edge laser technology with precision engineering to deliver exceptional part quality and production efficiency.

The robust architecture supports high-throughput manufacturing of complex geometries across a comprehensive range of specialized metal alloys. With configurable laser options and intelligent powder management, the system ensures optimal performance for critical applications in aerospace, medical, automotive, and energy sectors.

Engineered for reliability and repeatability, our solution provides manufacturers with the tools to push the boundaries of metal additive manufacturing while maintaining strict quality standards.

Key Advantages:

-

Multi-laser configuration for scalable productivity

-

Broad material compatibility for diverse applications

-

Precision optics system for fine feature resolution

-

Optimized build process for consistent results

-

Industrial-grade construction for continuous operation

Transform your production capabilities with a system built for industrial-scale metal additive manufacturing. Contact our team to discuss how this technology can enhance your manufacturing workflow.

#Industrial3DPrinting #MetalAM #AdditiveManufacturing #DigitalProduction #AdvancedManufacturing